What is a tapping machine used for

A tapping machine, also known as a tapping device or a tapping tool, is a mechanical device used to create threaded holes in various materials. It is commonly used in metalworking, woodworking, and other industries where threaded connections are required.

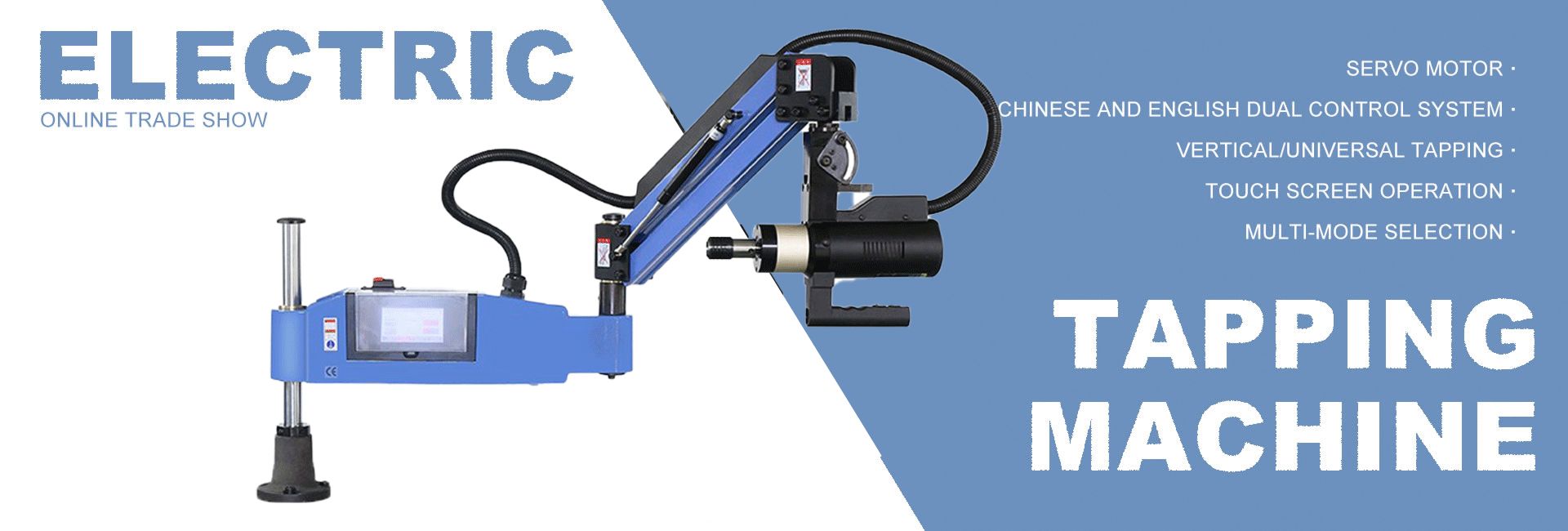

The tapping machine automates the process of creating internal threads, which are typically used to secure bolts, screws, or other fasteners into a workpiece. The machine consists of a motor-driven spindle, a tapping head or chuck, and a mechanism to control the feed and rotation of the tap.

Here's a brief overview of how a tapping machine works:

1. Set up: The workpiece is securely clamped in place, either vertically or horizontally, depending on the machine's configuration. The tapping machine is positioned above the workpiece.

2. Tool selection: The appropriate tap size and type are selected based on the desired thread specifications and the material being tapped. Taps come in different sizes, thread pitches, and shapes to accommodate various requirements.

3. Alignment: The tapping machine aligns the tap with the pre-drilled hole or marked location on the workpiece.

4. Operation: The motor-driven spindle rotates the tap at a controlled speed while applying axial force to facilitate cutting the threads. The tap's cutting edges engage with the workpiece and progressively create the internal threads.

5. Reversal and extraction: Once the tapping is complete, the machine reverses the rotation of the tap to break the chips and clears them from the hole. The tap is then retracted from the workpiece.

Tapping machines offer advantages over manual tapping processes. They provide consistent and precise thread cutting, higher production rates, reduced operator fatigue, and improved thread quality. They are particularly useful when dealing with larger workpieces or when multiple threaded holes need to be created quickly and accurately.

It's important to note that tapping machines can vary in design and features depending on the specific application and industry requirements. Some machines may have additional capabilities, such as automatic feed control, depth control, and coolant systems, to optimize the tapping process and enhance productivity.

Latest News

Contact Us

Name: Nina

Tel: 0086-0769-81177281

Fax: 0086-0769-81177281

Mobile: 0086-13712515491

E-mail: [email protected]

Skype: toolsharpener

QQ: 19641516791

WeChat: 0086 13712515491

Whatsapp: 0086 17727718926

Add: No 1 industrial avenue, Hengli Town,Dongguan city,Guangdong provience,China

CHINESE

CHINESE ENGLISH

ENGLISH

Skype Chat

Skype Chat WhatsApp

WhatsApp  Mail inquiry

Mail inquiry QQ online

QQ online