Principle of a Tapping Machine

Principle of a Tapping Machine

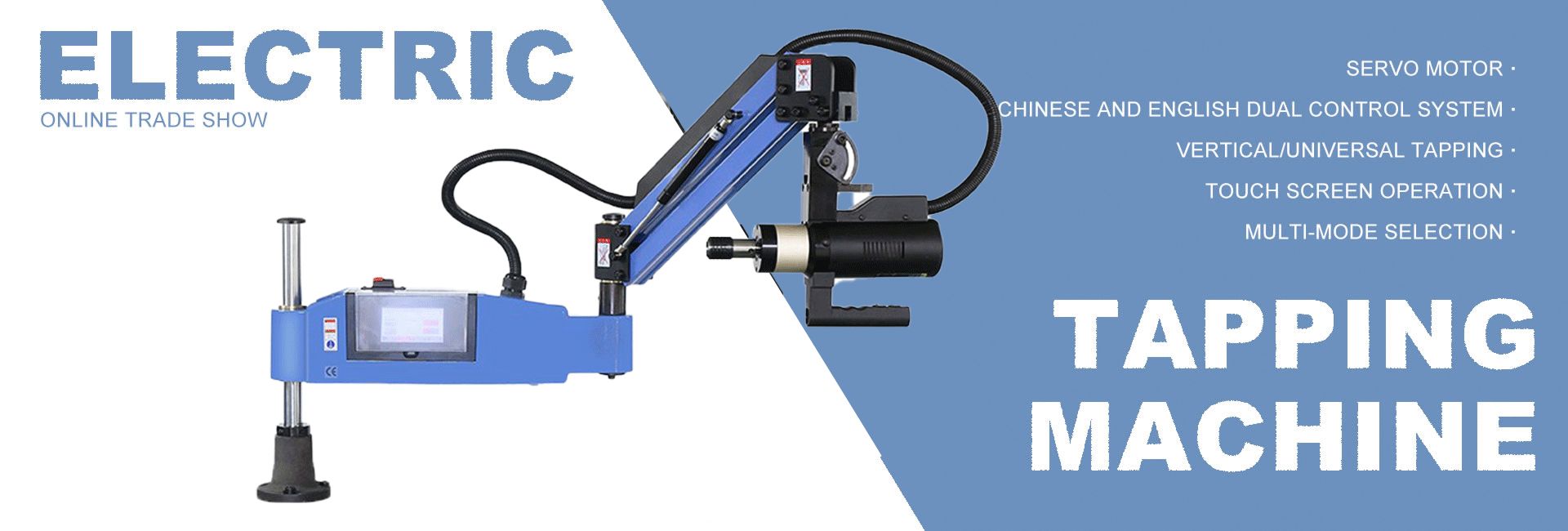

A tapping machine is a device used for creating internal threads in various materials. It operates based on the following principles:

1. Rotation: The tapping machine utilizes a motor to rotate the tap. The tap is a cutting tool with helical grooves that matches the desired thread profile.

2. Feed: The tapping machine provides a controlled axial movement to advance the tap into the workpiece gradually. This movement is often achieved through a lead screw or a ball screw mechanism.

3. Cutting Action: As the tap rotates and moves forward, it engages with the workpiece's pre-drilled hole. The cutting edges of the tap remove material, creating the internal thread.

4. Chip Removal: During the tapping process, chips or swarf are generated as the tap cuts through the material. Proper chip removal mechanisms, such as spiral flutes on the tap or coolant/lubricant, help evacuate the chips from the hole.

5. Reverse and Retract: Once the desired thread depth is achieved, the tapping machine reverses the rotation of the tap and retracts it from the workpiece. This action prevents damage to the newly formed threads and facilitates the removal of the tap from the hole.

6. Control and Automation: Modern tapping machines often incorporate advanced control systems that enable precise speed, feed rate, and depth control. These systems may include sensors for monitoring torque, depth, or tool wear, ensuring accurate and reliable threading operations.

By following these principles, tapping machines provide an efficient and automated solution for creating internal threads, reducing manual labor and increasing productivity in industries such as manufacturing, construction, and automotive.

Latest News

Contact Us

Name: Nina

Tel: 0086-0769-81177281

Fax: 0086-0769-81177281

Mobile: 0086-13712515491

E-mail: [email protected]

Skype: toolsharpener

QQ: 19641516791

WeChat: 0086 13712515491

Whatsapp: 0086 17727718926

Add: No 1 industrial avenue, Hengli Town,Dongguan city,Guangdong provience,China

CHINESE

CHINESE ENGLISH

ENGLISH

Skype Chat

Skype Chat WhatsApp

WhatsApp  Mail inquiry

Mail inquiry QQ online

QQ online