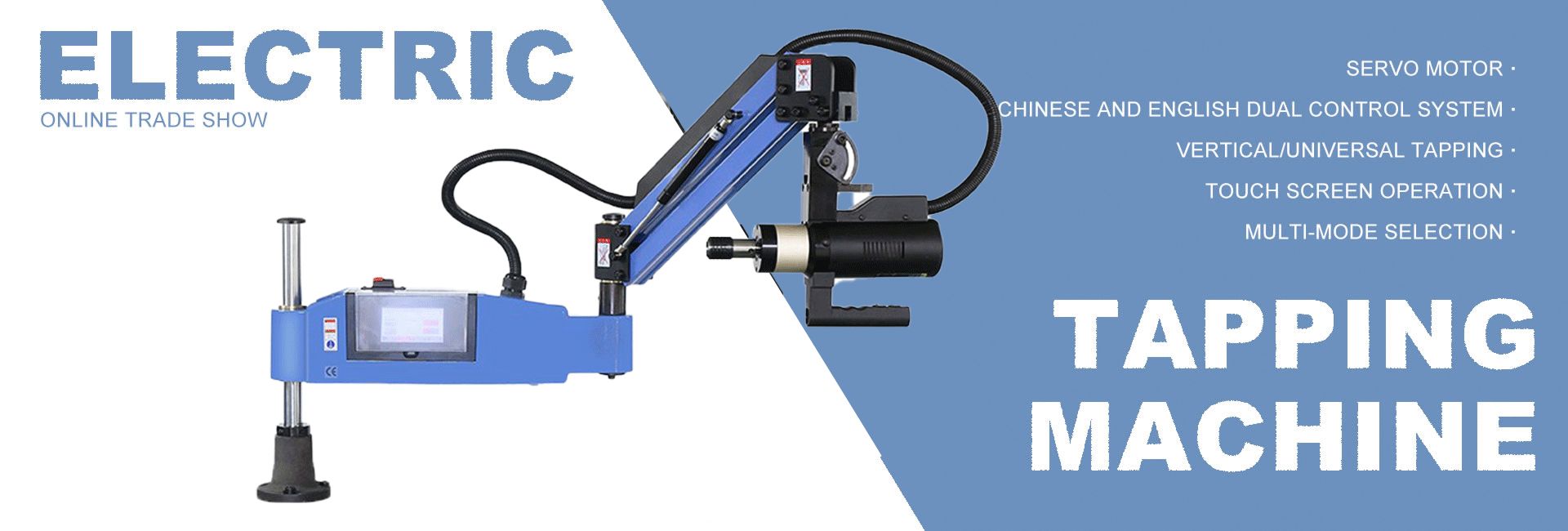

Summary of principles, features, and usage of electric tapping machine

Electric tapping machine is an essential tool in production, which can be used for internal threading of coarse teeth, fine teeth, non-standard pitch, forward and reverse fastening connection threads, transmission connection threads, and pipe threads of various small and large steel parts, and can meet the requirements of thread tapping below M42. Most mechanical processing industries and mold industries are enjoying the convenience brought by electric tapping machines. Today, the Xiaojie website editor will introduce to you the principle, composition, characteristics, use, and daily maintenance methods of electric tapping machines one by one.

Working principle of electric tapping machine

The electric tapping machine delivers lubricating oil to the tapping machine motor through the double connector and filters out the water generated by the air compressor. Therefore, when adjusting the pressure, you can pull up the knob before rotating it and press down the knob for positioning. Turning the knob to the right increases the outlet pressure, and turning it to the left decreases the outlet pressure. When adjusting the pressure, it should be gradually and uniformly adjusted to the required pressure value, and should not be adjusted in one step. If you want to improve production efficiency, you can install a multi-axis tapping machine. In short, the electric tapping machine is based on the fixed seat as the origin, and the rotating arm and the extended arm as the working radius, and can easily tap threads at any point within the working radius.

Composition of electric tapping machine

1. Servo motor: drives the controlled object by converting the voltage signal into torque and speed;

2. Bracket: height-adjustable, can tap threads at any position within the operating radius;

3. Controller: power control and torque overload protection;

4. Display screen: control and adjust the speed of thread tapping;

5. The machine body is equipped with a lifting mechanism that can lift the main spindle Z axis by 120mm;

6. The thread cone torque protection chuck can adjust the size of the chuck torque. If the tapping exceeds its torque when tapping to the bottom of a blind hole, it will slip and protect itself.

Characteristics of electric tapping machine

1. The electric tapping machine has a large torque and a constant working torque, which means that the tapping efficiency and speed are constant.

2. The electric tapping machine is easy to achieve automatic control, and it is easy to achieve special control methods such as depth control and other special requirements. It can communicate with PLC and other control modes. Other control units can control the speed and position of the servo motor to achieve various action modes, and it has the characteristics of high threading accuracy, fast speed, and high quality.

3. The electric tapping machine is almost applicable to all mechanical manufacturing industries, such as machine tools, molds, plastics, printing, engineering, automobile parts manufacturing, etc. It is equipped with a universal head, which can tap threads vertically or horizontally. If there are larger workpieces, it can tap threads without moving the workpiece. Similarly, it can also be applied to various light industrial operations.

4. Compared with the manual era, the electric tapping machine has high work efficiency, saves time and effort, and has high thread accuracy.

5. The electric tapping machine is not easy to break teeth, and the thread cone is not easy to break.

6. Compared with pneumatic tapping machines, it solves the problem of unable to tap threads due to insufficient air pressure, can set the depth and torque value of tapping, and protect the thread cone from overload and breakage to the greatest extent.

Latest News

Contact Us

Name: Nina

Tel: 0086-0769-81177281

Fax: 0086-0769-81177281

Mobile: 0086-13712515491

E-mail: [email protected]

Skype: toolsharpener

QQ: 19641516791

WeChat: 0086 13712515491

Whatsapp: 0086 17727718926

Add: No 1 industrial avenue, Hengli Town,Dongguan city,Guangdong provience,China

CHINESE

CHINESE ENGLISH

ENGLISH

Skype Chat

Skype Chat WhatsApp

WhatsApp  Mail inquiry

Mail inquiry QQ online

QQ online